RFID Enterprise Asset Management Application

find, count & measure your assets simply and cost effectively

Reducing operational costs and improving

profitability are just the beginning. A comprehensive Enterprise Asset

Management solution powered by Xinye RFID tags,which enable enterprises

around the world to better manage, maintain and track their assets. It

has never been easier that making strategic business management

decisions to improve performance every day.

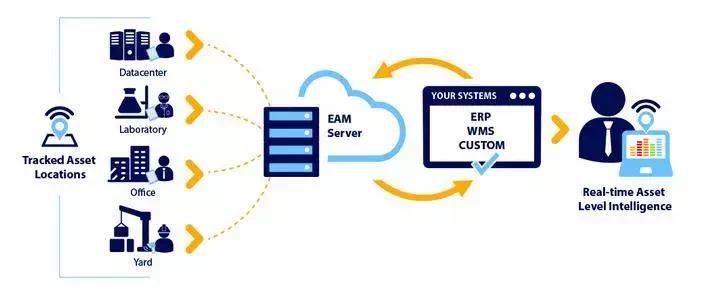

Xinye’s solutions are generally used

across all industries from IT and lab asset management,yard management

in the construction and energy industries, retail, medical as well as

manufacturing and logistics applications. Whether you are seeking a

simple method for inventory counts or a whole-new asset management

solution, xinye is here!

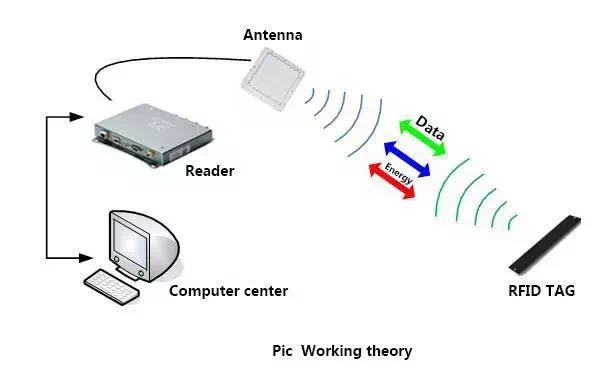

Complete IoT Based Solutions: Hardware, Software, Services

All this starts from the tags, and xinye

has the largest passive and active RFID tags in the industry.RFID is the

most cost-effective of the IoT solutions. IoT-enabled assets provide

you with real-time visibility into asset performance and allow you to

effectively manage the entire asset life cycle.From the moment an asset

enters your facility to the moment it is retired, You can view the

status, location, and current value of each asset accurately in real

time. This allows you to focus on delivering operational and financial

efficiency that manual tracking can’t do.

The Construction of Function :

When asset in storage,the management

system of asset set a new record.And make connection with RFID via GUID

code. The format of tags can be designed freely,so that everything can

be documented.The only identification code of terminal assets rely on

the vendor bar code.While non-terminal assets using the RFID globe code

in accordance with uniform rules.The system should have the function of

restoring the barcode when the bar code is worn and can be printed out

.The note of associate ID: To manage the assets and device tags via

GUID.

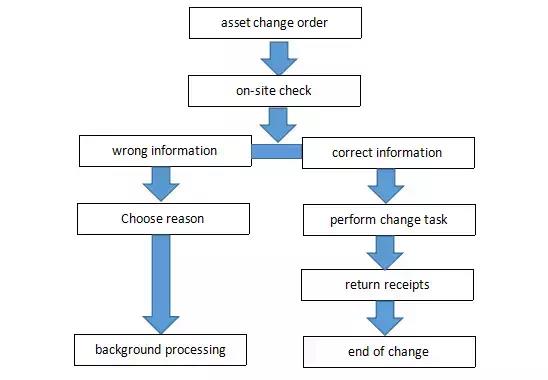

2.Asset information change

When asset information changes (including

location information), track asset change orders through hand held

devices. Change work order process:

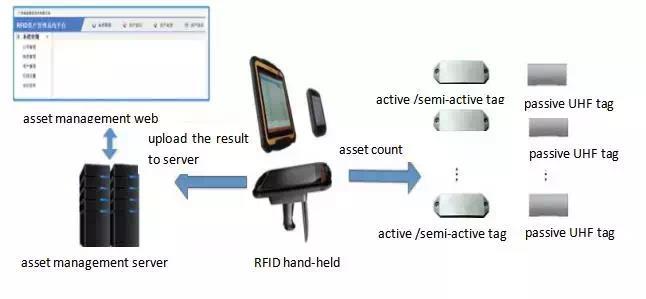

3.Asset Count

When do asset count, we use the hand-held

inventory device to scan the barcode tag(RFID) of assets,the data in

the inventory and the data in the database are checked,and the abnormal

data will be done properly.Except that, the balance,the loss

schedule,the inventory summary table can be generated by company or by

department. The asset inventory including financial count and and

maintenance count(including location information).In the process, the

hand-held device is supported, and following functions is supported:

1),Support offline mold. The basic data

which download from the Internet by the hand-held device ,the device

that could be used by offline mold and upload the before count data.

2),Support multiple counts and abnormal repeated counts.The abnormal device will do the count task again,and eventually perfect!

3),Inventory function is divided into financial count and maintenance count.

4),The count process:

This can be divided into two part:

1)Abnormal alarm of inventory:Abnormal inventory data alarm includes financial inventory abnormal alarm and maintenance inventory alarm. Financial inventory alarm mainly includes asset quantity check, warning list for abnormal results. Maintenance inventory contains equipment location information alarm of the data and asset equipment.

2),The access warning assets without authorization,and access to the monitoring area,the alarm will be issued in real time, and the query can be made through the history record .

System Advantage

1,Each item is given a unique identity.

2,The information in the device can be got convenient and fast, the RFID reader knows the item information by contactless style, and the tag’s life will be longer.

3,The data storage capacity in the electronic tag is up to 512 bits, which can meet the requirements of the data recording of the regular items from purchasing to scrapping.

4,Recognition fast. RFID tool management has a quick scan, can get thousands of information of tools within a second.

5,Data storage time is long. The information written to the RFID tag can be stored for more than 10 years and the use information of the item could also be traced back more than 10 years.

6,The tag can be used repeatable.The data information in the electronic label can be erased and be written more than 100000 times.Thus, which meet the need of add ,modify ,delete and other operations of tool information.

7,The RFID tag can read the information with penetration and no barrier. The electronic tag management system can identify the property information of non-metal materials such as paper, wood and plastics.

8,High security. Because the RFID tag carries electronic information, data content and operation, it can be protected by 32-bit password, which makes its content difficult to be forged and changed illegally.

9,A statistic data counted by IDC, said that , a complete asset management system can help enterprises and institutions to achieve:

Reduce 75% audit cost;

Decrease 40%spare parts;

Reduce 20%extra test machine;

Reduce 45% missing of the equipment;

Improve 30% asset utilization;

Delay 10% equipment operation life;

Reduce 50%downtime of the machine;

Eliminate 99% capital asset withdraw.

10,Improve the speed and accuracy of asset management, so that all kinds of asset management can be implemented.

Connection Products of Solution